Does anyone even really know what “411” is anymore or have I dated myself? I digress…

In offices buildings, lighting can account for 15%- 20% of energy use. Lighting controls, when properly used, can reduce that by 25%. Because there are diverse types of controls technologies and applications, it is recommended to game plan accordingly.

First used in the 70’s as an alternative to microwave and ultrasonic motion detectors, Passive Infrared (PIR) detectors promised lower costs and false alarms. The technology originated at Optical Coating Labs in California. PIR motion detectors use thermal sensors which detect small temperature increases. Ultrasonic motion detectors detect occupancy by sending out ultrasonic sound waves into a space and measure the speed at which they return. As movement by a person occurs, frequency changes and triggers the sensor.

When sensors are used correctly they can be highly efficient at saving energy, keeping occupants safe and keeping lighting fixture maintenance costs low. When used incorrectly, sensors can be a burden on occupants and cause more headaches than they cure.

New and improved sensor technology make it so occupants never give the sensors a second thought. With dual technology sensors, unless an occupant is napping under his/her desk, there is no worry of lights being turned off while an occupant is in the room. With switched plugs clearly marked, occupants don’t have to worry about PC’s being shutdown improperly and unexpectedly.

Let’s talk a little more about the basic technology behind occupancy sensors:

Passive Infrared Motion Detection

PIR (Passive Infrared) occupancy sensors are best used for detecting large or major motion like an occupant walking through a space. PIR works by detecting movement of heat sources in the space. It can only detect heat in its direct range of view and its cover is directional and limited to line of sight. Thus, planning and design are key with this type of technology. Since PIR only detects large movement, they are prone to false offs. Here is an example of a Wattstopper PIR ceiling sensor CI-355:

Ultrasonic Motion Detection

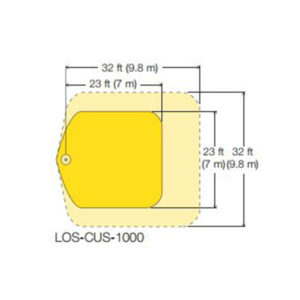

Ultrasonic technology in occupancy sensors is used for minor or small motion detection. This makes ultrasonic an appropriate choice where small movements, such as working at a desk, takes place for extended periods of time. As previously mentioned, ultrasonic works by emitting an ultrasonic sound wave into the space and measuring the frequency. When there is movement in the space, the signal bounce back is read differently and the sensor knows there is movement in the space. Ultrasonic technology can detect motion even around corners. Limits to this technology include: higher power needs and false triggers. Here is an example of a Lutron ultrasonic ceiling sensor LOS-CUS-1000-WH:

Dual-Tech Motion Detection

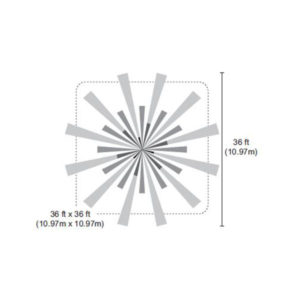

Like it sounds, dual-technology combines both ultrasonic and PIR sensor technologies to provide optimal detection, with minimal false reads. The occupancy sensor will not turn on the lighting until both PIR and Ultrasonic elements are triggered. Once a light is turned on, the sensor only needs one of the technologies to keep the lights on. This helps ensure the lighting is not turned off while the occupant is in the space. Dual-technology sensors are more expensive (though not much), but are more effective. Here is an example of a dual technology ceiling sensor from Wattstopper DT-355:

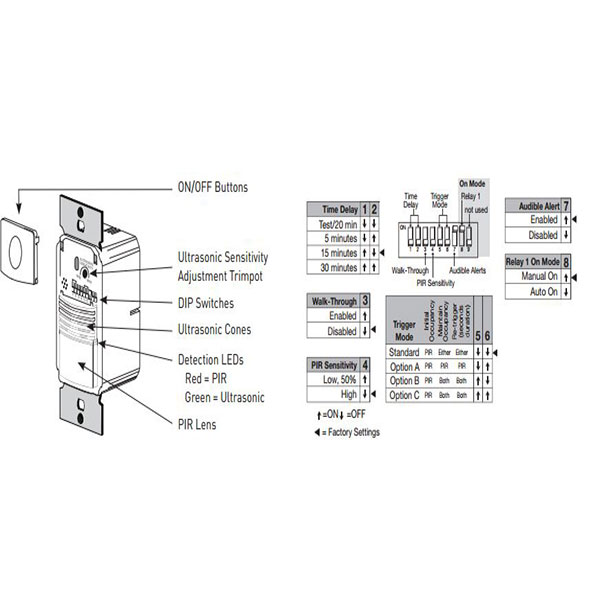

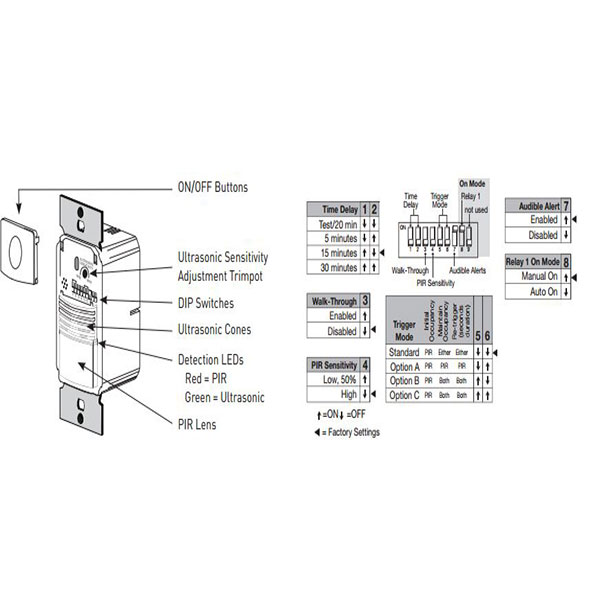

Here is an example of a dual technology wall mount sensor by Wattstopper DSW-100:

Occupancy with Daylight Sensor

Some occupancy sensors are equipped with a daylight sensor that allows the installer to set a light level at which the occupancy sensor will not trigger the lighting on based on daylight in the space. So, the end user can save additional money by not using lighting if the space does not require it based on natural light. Generally, you can adjust sensitivity according to your interest. These are only used to detect the lighting in the space to switch lighting on or off, depending on the light levels and they are not applicable to certain energy codes that require daylighting and dimming requirements.

Occupancy vs. Vacancy Sensors

Occupancy sensors generally are equipped with Auto –On setting so when an occupant enters the room, the lights turn on. Some have the ability to switch to a Manual- On, a vacancy setting, meaning that the lights will turn on only if the occupant turns the light on at the switch. However, it will detect movement and keep the lights on until the occupant leaves the room, at which point the sensor will detect vacancy and turn the lights off.

Have questions about which sensor is right for your job? Contact us at literitecontrols.com and we can help. Already have sensors in mind? Check out literitecontrols.com for the best pricing.